Offer

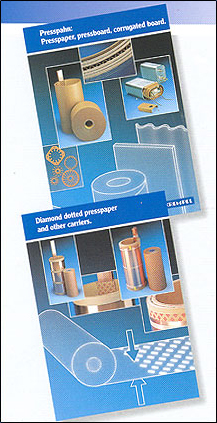

1. Preshpan insulating material

Preshpan is a reliable cellulose-based surface insulation material for Class A insulation materials.

Depending on the grade of cellulose, fibre pre-treatment and machine settings, different types of

precipitate with very specific properties are obtained.

Preshpan is a reliable cellulose-based surface insulation material for Class A insulation materials.

Depending on the grade of cellulose, fibre pre-treatment and machine settings, different types of

precipitate with very specific properties are obtained.

The characteristics and material properties of the precipitate are defined in DIN 7733 and IEC 641. In

addition to the high electrical puncture resistansce and high ease of impregnation with transformer oil

(mixed oil-cellulose dielectric), it is particularly worth emphasizing that the precipitate does not have a

specific flushing temperature. Therefore, it can withstand short-term thermal loads (e.g. a few seconds at

350°C) without any significant loss of its properties. Prespan can be pressed, crushed, punched and partly

formed.

Transformer preshpan in sheets of size:

od 0,10 mm -4,0 mm 1000x700 mm

od 0,10 mm -8,0 mm 2070x1000 mm

1,0 2,0 3,0 4,0 2200x4200 mm

in rolls from 0,10 - 1,0 mm 1000mm lub 2000 mm

Click and see the

table "Standard grades - Precipitate in rolls and sheets"

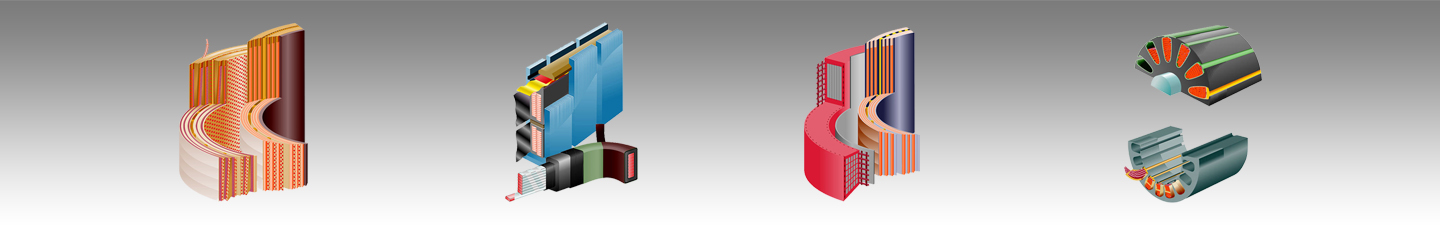

2. Multilayer insulating materials

Flexible multilayer insulating materials are obtained by bonding plastic film with precipitate, fibres,

fabrics or plastic paper. These materials are most often produced in a three-layer version with the middle

layer being a plastic film. Depending on the choice of starting components, the resulting flexible

multilayer insulation materials are characterised by very specific properties such as operating temperature,

flexibility, tensile strength, elongation, puncture strength, impregnation ability and

stiffness.

Flexible multilayer insulating materials are obtained by bonding plastic film with precipitate, fibres,

fabrics or plastic paper. These materials are most often produced in a three-layer version with the middle

layer being a plastic film. Depending on the choice of starting components, the resulting flexible

multilayer insulation materials are characterised by very specific properties such as operating temperature,

flexibility, tensile strength, elongation, puncture strength, impregnation ability and

stiffness.

The combination of plastic films and fibrous materials brings both technical and economic benefits. By

bonding, the specific properties of the individual components can be ideally exploited. In this way, plastic

films provide excellent electrical and mechanical properties, while fibrous materials are easy to impregnate

and protect the film. This combination increases the tear and tear strength, improves the bending and

punching properties and protects the film from the harmful effects of oxidation and hydrolysis. Flexible

multilayer insulation materials allow cutting, bending, extrusion and, within certain limits, hot and cold

forming.

Click and see the

table "Standard grades of flexible multilayer insulating materials"

3. Special insulating papers

Special insulating papers used to insulate elements in transformers and other electrical power equipment

such as:

- crinkled paper

- crinkled paper tubes

- cable paper (transformer paper)

- creped semiconductive paper (black)

- Semi-conductive paper smooth (black)

- DPP paper - DDP resin-spotted

- paper tape reinforced with glass fibre thread

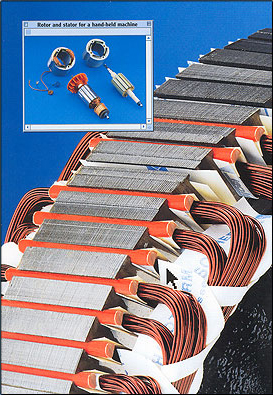

4. Prepreg insulating material

Prepregs are obtained by impregnating or coating preshpan, papers, fibres, fabrics, foils or multilayer

insulating materials with a variety of thermosetting insulating resins, which are characterised by the

reaction state B.

Prepregs are obtained by impregnating or coating preshpan, papers, fibres, fabrics, foils or multilayer

insulating materials with a variety of thermosetting insulating resins, which are characterised by the

reaction state B.

Prepregs are used in the manufacture of transformers and electrical machines for insulating and

strengthening winding elements. The advantage of these high-quality materials is that they are used as

impregnating

agents (uncured artificial resins) and are placed with the surface insulation in grooves or wound with the

foil on the windings. In the further curing process of the resin, the insulation is glued to the electrical

conductors. Prepregs can be further processed very easily.

Click and see the

table "Prepreg standard grades"

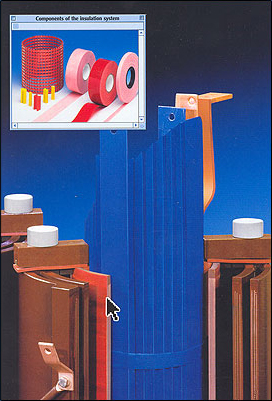

5. Plastic reinforcing plates and fittings.

Under the name "PREGNIT®" we produce fibre-reinforced plastic plates which are pressed according to customer

specifications. By deliberately selecting the type of fibres, resins and material structure to take into

account the future use of the panels for a wide variety of applications, opening up new construction

possibilities. Fibre-reinforced plastic plates can be machined with both hardened steel tools and diamond

tools without any problems. The most common processing methods are cutting, drilling, grinding and

turning.

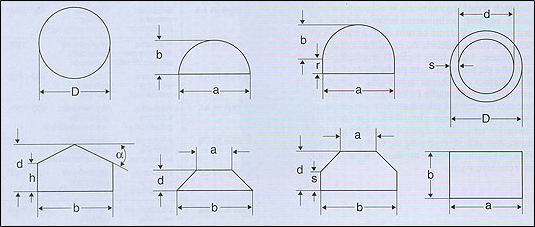

Many constructional problems can only be solved if you have fittings with precisely defined dimensions and

properties. In industrial electrical equipment, spring grooves made of fibre-reinforced plastics are used

for locking the winding rods and for damping, while conductive lateral groove springs ensure contact between

the heat protection of the winding rods and the groove wall. Inlet springs are much easier to install in

grooves than fibreglass-reinforced plastic panels (GRP).

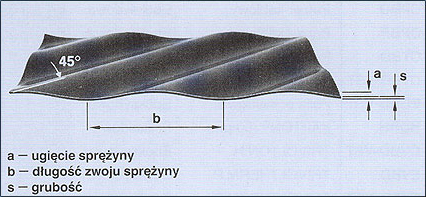

Below the structure of the electrically conductive lateral groove spring.

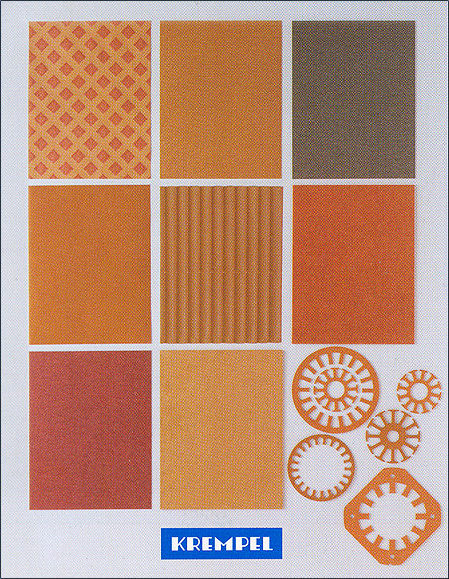

6. Electrically conductive surface materials.

Current-conducting nonwovens and fabrics are obtained by impregnating nonwovens and polyester fabric or

glass fibres with binding agents containing different concentrations of conductive particles. In this way,

any surface resistances from 100 to 20,000 Q/D can be achieved using the same carrier. The binders are

cured. For special applications, electrically conductive impregnated glass fabrics - Prepregs electrically

conductive fabric laminates are produced.

Electrically conductive surface materials are used in machines, transformers and high voltage cables to

provide general insulation, increase operational safety and extend the service life. Although they are

actually dealing with marginal problems in the field of high-voltage technology, they should be given a

great deal of attention. Depending on the scope of application - whether as insulating materials (non-woven,

conductive fabric) or as keyway filler materials (conductive GRP panels and GRP springs made of glass fibre

reinforced plastics), they must have a number of specific mechanical, thermal and electrical properties.

Click and see the

table "Standard grades of non-woven conductive fabrics"

7. Fibre-reinforced plastic profiles.

Under the name "WACOSIT®" we supply "Pultrusion" pipes and drawn profiles. Rovings and/or narrow woven

glass, carbon or polyamide tapes impregnated with modified epoxy or polyester resins are used as reinforcing

material and are then cured. As a result of the high tensile force of the "Pultrusion" process, the resin is

pressed into the free spaces between the fibres. In this way a homogeneous bond is achieved.

Due to its excellent mechanical, electrical, thermal and chemical properties, "WACOSIT®" is used to solve

difficult structural problems. Profiles and pipes are characterized by high surface smoothness and reliable

dimensional tolerances. For this reason, additional finishing is not necessary. We currently have tooling

for more than 2,000 standard profiles - special profiles are a matter of course for us on request.

8. Sealing materials

9. Components for solar panels

ELECTRICALLY

Preszpan

MATERIALS

ELECTRO-INSULATED

PAPERS

INSULATION